ABNORMALLY LARGE WORKSHOP FABRICATED STORAGE VESSEL TRANSPORTED TO CLIENTS SITE FOR INSTALLATION

People watched as the largest tank to be transported into Sasol, a fully fabricated and Erected Tank, since the operation of Sasol Secunda in 1976, was transported into Sasol Plant.

Those residents that were living in Secunda, and some working at Sasol, will remember the days of large pieces of the plant were transported by road into the factory area.

Each one is bigger than the next, until now.

At 78 tons and a minimum of 15.8m in diameter and 17.5m in height, this would prove to be a mammoth task to transport. Everything needs to be considered. The wind, the road surface, areas to be able to turn and overhead cables. Even the congestion of traffic was considered.

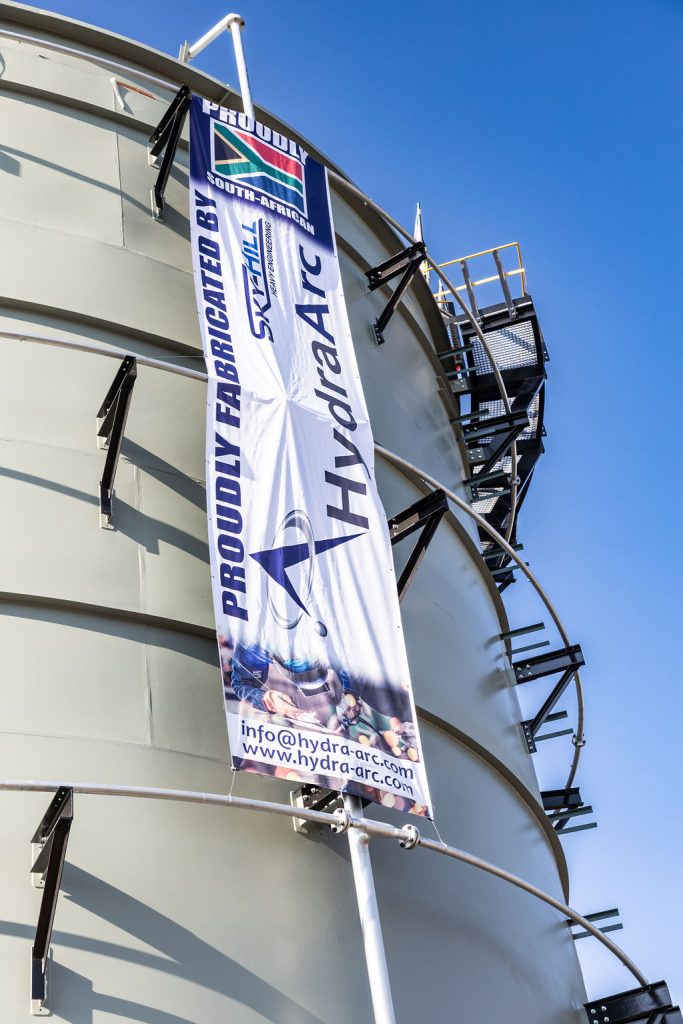

The tank was supplied by WOOD PLC as the contractor with Hydra-Arc/Sky Hill as the sub-contractor. Sasol Secunda Tank Farm was the end user.

The request was submitted in 2021 already for a Budget Proposal:

Tyrone van Heerden, PMO Manager and Project Manager for Sky-Hill

“We were initially requested to submit a budgetary Proposal in May 2021,” said Tyrone van Heerden, PMO Manager and Project Manager for Sky-Hill, “At the time of providing the Original Pricing Proposal, we issued our Commercial offer in line with the original scope calling for On-Site Fabrication and Erection of the tank. We did concurrently investigate the Full fabrication and Erection of the tank at our Sky-Hill Fabrication Facilities, and the transporting of the tank undressed (Meaning no walkways and Fire Suppression Deluge System installed which would be installed onsite) to site.”

“Upon Conclusion of our Investigation, with the Contractor, we established that the cost savings were proven and significant, the feasibility of this major undertaking, the risks associated and Schedule Benefits, aligned to build the Storage tank as One Unit, as against an onsite build.” Said Tyrone

Also read: ANIMALS 101 – ARE YOU A RESPONSIBLE PET OWNER?

Preliminary Transport route surveys and the investigation of other similar projects showed that it was possible to transport the Storage Tank with the diameter of the tank being 13.75m in total, considering both the road limitations and Plant Congestion.

As they proved the viability of fabricating and Transporting the Storage Tank as a Single Unit and well below the Originally Priced Onsite Build, the contractors received an RFQ in Aug 2022 requesting a Commercial Offering on the revised option which was submitted in the middle of August 2022.

The order was placed at the beginning of September 2022.

The project scope included a full turnkey project with the Management, Design, Procurement of materials and sub-contractors, Fabrication, Painting / Galvanising, Transporting, and Rigging of the tank into position on site.

“Luckily, the Contractor knew our Capabilities and if we said we could do it, we would do anything in our power to reach the Contractor deliverable to the client,”

Tyrone van Heerden, PMO Manager and Project Manager for Sky-Hill

“Once the Tank is placed, and rigged into position, we were to install the walkways, platforms and install the fire Suppression deluge system. We were also required to complete the Storage Tank stand test and the Tank Gauging and Strapping’” said Tyrone.

As the transport was the biggest risk and the biggest deliverable, they needed to prove within 20 days it could be definitively done without any risks that were “show stoppers”.

The design commenced in parallel with their alternative offer proposal. They (Hydra-Arc/Sky Hill) met their deadline, and it was decided to go ahead with this option by managing the risks and establishing the Best Engineering practices to Deliver the Project on time, In Budget and Ahead of Schedule.

“Luckily, the Contractor knew our Capabilities and if we said we could do it, we would do anything in our power to reach the Contractor deliverable to the client,” said Tyrone.

As they continued with the Project, they continued to look for opportunities to mitigate risks but also optimise their offering to the Contractor and ultimately the End User.

During one of their risk mitigation and optimisation sessions, an alternative route was identified due to another large project being underway that they were not aware of and which allowed them through an alternative access route West of the Plant with much less congestion.

This would now allow the transportation of the entire tank including the walkways, platforms and deluge system fully installed, essentially removing any construction work being required within the Primary Area of Sasol Secunda, as previously planned. This option was then taken.

“With this revised option, the fully dressed storage tank would need to be transported at a minimum of 15.8m in diameter and 17.5m in height, making this the largest tank to be transported into Sasol as a fully fabricated and Erected Tank, since the operation of Sasol Secunda in 1976.” Said Tyrone

Some technical Details on the Tank and Project are as follows (supplied by Hydra-Arc/Sky Hill:

- The tank weighs 78 tons.

- The total transport weight is 190 tons.

- The total super lift weight is 94.2 tons with a boom radius of 45.5 meters and a boom height of 63 meters.

- The Transport width of the tank will be 16.5m and the height will be 17.52m.

- The route length is a total of 22km.